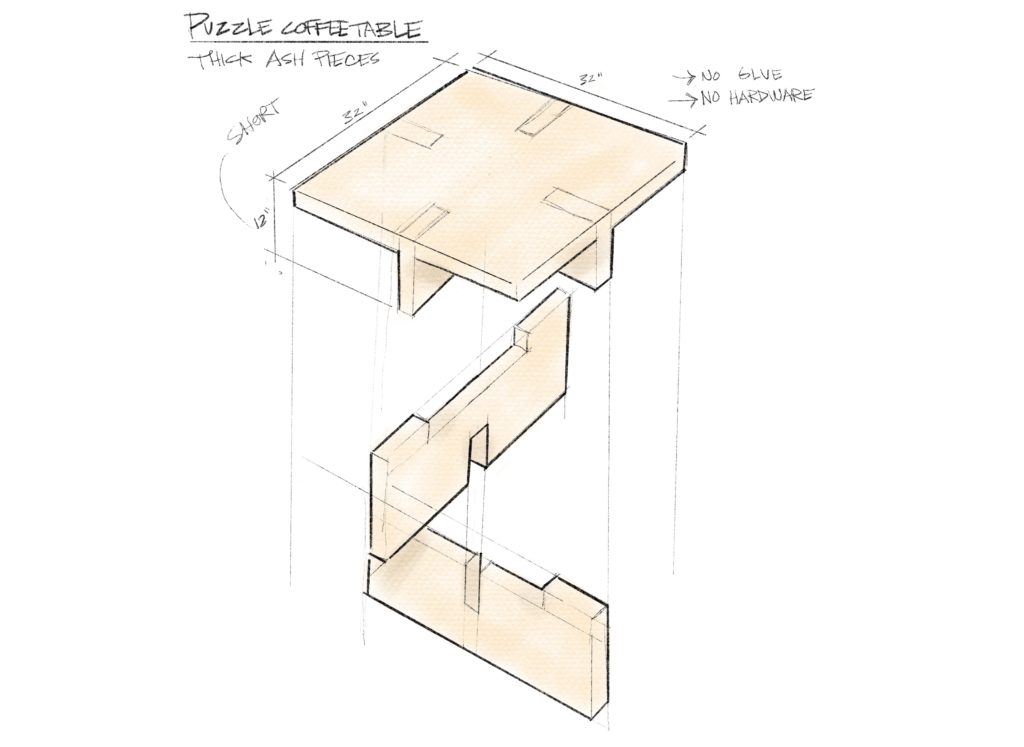

A Minimalist Coffee Table – No Hardware Required

The goal was to design a minimalist coffee table that didn’t require any hardware to assemble.

Joinery

We love seeing joinery come together. (It’s hard to imagine someone who doesn’t.) We wanted a minimalist coffee table that didn’t need any hardware or glue, but despite the name, it wasn’t complicated to figure out how the pieces come together. Rather than having a top and four legs that fit together in a complex (but admittedly amazing) way, the concept was to take one joint and scale it up to the size of a table.

There was a practical reason for wanting to design a piece of furniture without complicated assembly: shipping and delivery. Some furniture arrives in large crates, already assembled, but we wanted to avoid shipping a lot of air.

Shipping furniture in pieces is efficient, but we don’t love anxiety-inducing instructions and making sure every bolt is accounted for. (It’s hard to imagine someone who does.) You can either take a chunk out of your Saturday to put it together, or the delivery team puts it together for you. Either way, the simpler we could make assembly, the better.

Simple is Hard

Although the concept was simple, production was an example where simple is hard. Each inside corner has to be carefully cleaned up and squared off by hand since a router uses a drill bit with a slight radius. Each piece also had to be precise to fit together nicely, without having to force it or having sloppy gaps. The quality and thickness of the material, direction of the grain, finish, and proportions were all details that had to be tested and refined for the final product to be successful.

Check out the final product here.